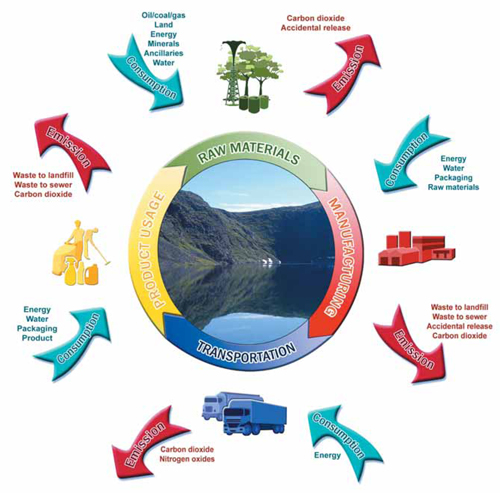

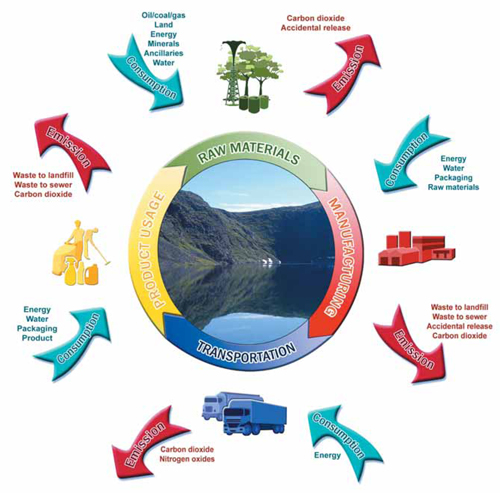

Sustainability is about meeting our own needs - in this context making things clean - without compromising the ability of future generations to meet their own needs. The general concept of improving sustainability is simple: Reduce consumption (to preserve the world’s natural resources) and reduce emissions (to minimise pollution).

Consumption and emissions will occur during a product’s manufacture, transportation, use and disposal. In many cases consumption and emissions are linked so reducing consumption in one area will bring benefits in other areas.

The term ‘life cycle’ is used to refer to all these stages in which impact occurs. The life cycle of a typical cleaning product is illustrated below: |

|

| Taking the simple steps described in this brochure will improve sustainability by lowering consumption and emissions of the following : |

Waste to landfill

Waste to sewer

Accidental releases

Carbon dioxide (CO2)

Nitrogen oxides (NOX) |

Oil / coal / gas

Minerals

Land use

Energy

Ancillaries (e.g. fertiliser)

Water

Packaging

Raw materials |

| |

| impacts during raw material production |

Raw materials, in the form of minerals, petroleum and plant-derived substances such as vegetable oils and wood-pulp,

are consumed to make ingredients and packaging for products. No source will be completely free from environmental

impact since energy will be consumed to make and transport all raw materials.

Other chemicals (such as agricultural fertiliser) may be used in the raw material production and wastes of various types

may be created.

As regards packaging, a high proportion of recycled fibre is already used in the manufacture of cardboard from which

cartons and boxes are made. Virgin fibre can be sourced from sustainably managed forests. Plastics used for

packaging should be chosen as far as possible to be recyclable. Guidance can be found under ‘Recyclability by Design’

at www.recoup.org. The overall use of packaging materials can be reduced by using refillable containers where practicable and by using efficient, concentrated products that do the job with the smallest volume of product. |

|

| impacts during product manufacturing |

To ensure products are manufactured sustainably, suppliers must work to reduce the impacts in this phase of the life

cycle. This should include:

Minimising raw material and finished product wastage during manufacture.

Minimising consumption of energy and water.

Minimising emissions to sewer and atmosphere and, in particular, controlling emissions of hazardous

substances to avoid risk to people or the environment.

Minimising packaging waste and recycling used packaging.

Operating an Environmental Management System.

Operating procedures to prevent accidental emissions.

Operating Occupational Health & Safety systems to protect staff.

The following are either regulated or are independently accredited and may prove useful in identifying responsible suppliers:

|

|

| impacts during product transportation |

As is the case for raw materials, transportation of finished products contributes significantly to the overall environmental

impact of cleaning, through energy use and vehicle emissions.

Increasing the effectiveness and number of doses contained on a pallet of cleaning products can help reduce these

impacts. Purchasing smaller volumes of more concentrated products is one way of doing this. Ensuring products are

used correctly and clean first time, without wastage, is another (see Impacts during product usage). |

|

| impacts during product usage |

Even when efficient, sustainably designed and produced products have been purchased, the overall environmental

impact of the cleaning process still depends very much on how the products are used. All the impacts in the life cycle

thus far can only be minimised if products are accurately and appropriately dosed. Overdosing by 20% not only wastes

money, but also adds 20% to all other impacts in the life cycle, including those arising during raw materials and

packaging production, manufacturing and transportation.

Key areas to focus on to ensure best environmental practice, minimal resource consumption and minimal emissions include:

Define what task the product has to do and buy products which deliver the required performance.

Analyse and reduce rework rates. First time cleaning is essential to minimise waste, particularly in energy

intensive operations such as machine dishwashing.

Favour more concentrated products, where applicable.

Dilute and use products according to the manufacturer’s instructions using accurate dosing systems where

appropriate.

Service cleaning equipment regularly, particularly critical items such as dosing pumps for automated machines.

Train staff, for example using BICSc courses. Offer instructions in a choice of languages where appropriate. |

|

| product design and ingredient selection |

The preceding sections highlight some of the impacts that arise during the cleaning product life cycle, and important

ways of reducing them. When a product is being designed and developed, it is the job of the manufacturer to find the

optimum balance that ensures effectiveness as well as safety, and minimises the overall environmental impact when

properly and diligently used.

Selecting ingredients is a critical step in designing a safe and sustainable product. However, ingredients need to be

considered not in isolation but as components in a complete formulation. The safety of a product depends not just on

the hazards of the individual ingredients but on the levels at which they are used in the product, on how the product is

used and people are exposed to it, and on how it is disposed of after use. As well as formulating to ensure safety,

manufacturers should look for opportunities to reduce the use of ingredients that are slow to biodegrade, especially any

which may have the potential to bioaccumulate, and should favour the use of ingredients where the margins of safety*

are wide. *See back page ‘Safety and Risk Assessment’ for further explanation.

Similarly, selecting ingredients only on the basis of their apparent individual sustainability can often reduce the

performance of the complete product, increasing total resource consumption. Sometimes, use of a small amount of a

seemingly less sustainable ingredient can markedly improve performance and/or allow major reductions in the use of

others. It is a common misconception that selecting ‘natural’ ingredients will inevitably improve the safety and

sustainability of a product. As explained on page 8, this is not the case. However as petroleum resources are finite,

manufacturers should look to favour sources of renewable feedstocks where these do not undermine sustainability in

other parts of the life cycle and can be farmed in a sustainable way.

Selecting ingredients for product safety

The ingredient recommendations on the following two pages will help to ensure that cleaning products are safe for

people and the environment when used as directed. These list all the major classes of ingredients, as set out in the

Detergents Regulation, and others which often appear in tender documents. They review important human and

environmental safety aspects of these ingredients, and any concerns that have been raised about them. They then

provide a current scientific assessment, based on the best available evidence, and give relevant guidance for

procurement in the UK of cleaning products used in the Industrial & Institutional (I&I) and Janitorial markets.

Requiring suppliers to exclude ingredients other than in accordance with this guidance is unlikely to have any significant

benefit and in some cases may seriously undermine the sustainability of the formulation. |

| |

| |

|

|

|